Canada is advancing toward net-zero through innovations in forestry and construction. The increased demand for renewable building materials is transforming design and architecture from coast to coast to coast. This transformation includes innovations in the combination of cross-laminated timber (CLT) and post-tensioned concrete.

Jonathan Wilkinson, Minister of Natural Resources, has announced a combined Government of Canada contribution of over $550,000 to the Hybrid Timber Floor System Project led by DIALOG and EllisDon. The project is funded through the Green Construction through Wood (GCWood) Program, a program that encourages the greater use of wood in construction and supports Canada’s transition to a low-carbon economy; and the Investments in Forest Industry Transformation (IFIT), a program that supports its recipients in de-risking the implementation of innovation in the Canadian forest sector.

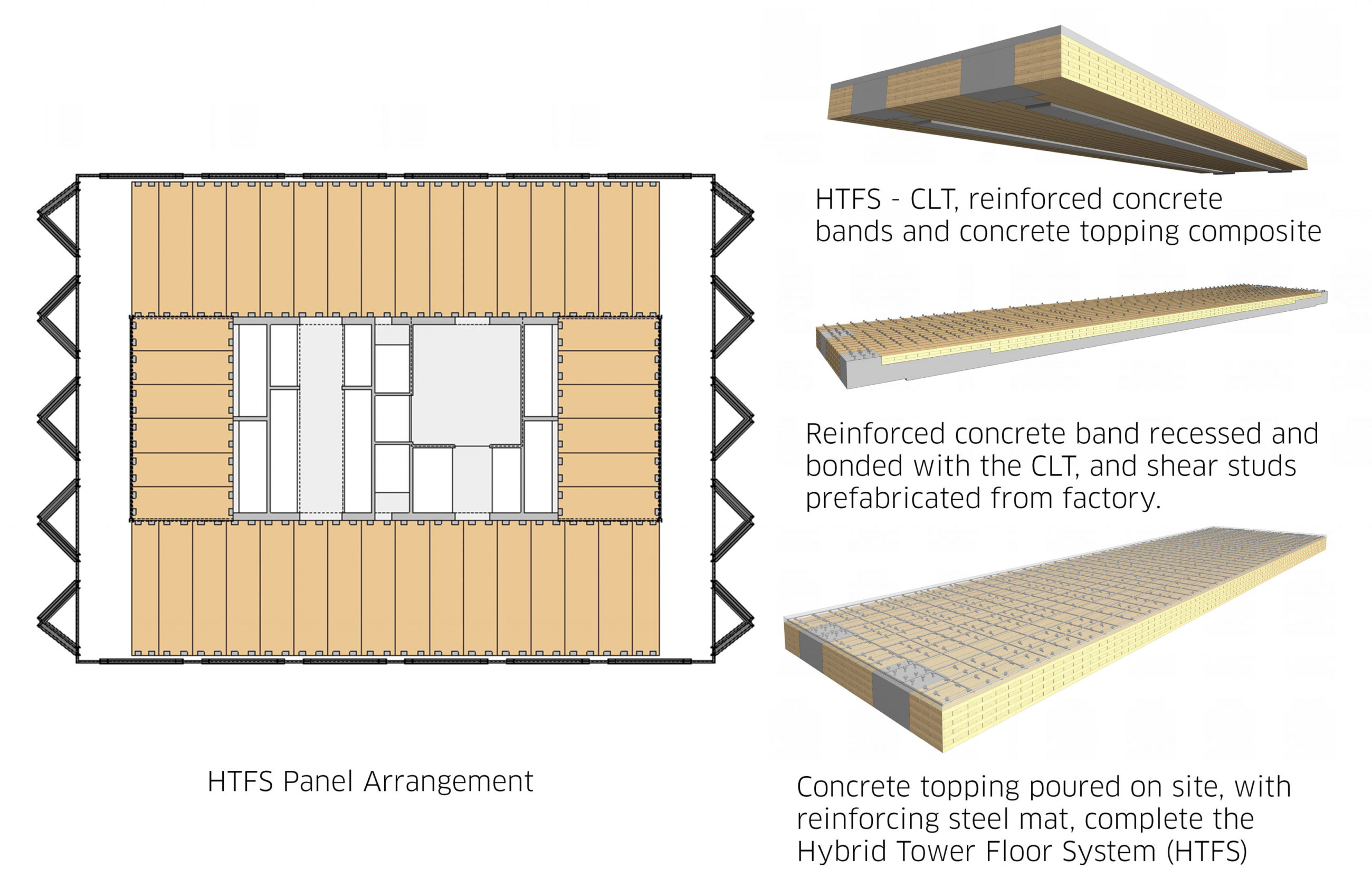

DIALOG and EllisDon’s patent-pending Hybrid Timber Floor System is an innovative approach to the existing concept of hybridizing structural materials. The Hybrid Timber Floor System, a mixture of different materials such as concrete and steel combined with mass timber, offers a reduction in carbon and an increase in building design possibilities. As a composite of post-tensioned concrete, CLT and a structurally engaged topping, it also allows mass timber–based floor systems to be used in non-residential long-span construction that had previously been limited to traditional building materials. This joint study with EllisDon looks at how this Hybrid Timber Floor System could allow mass timber to be used to meet the clear spans often desired in the commercial and institutional sectors while delivering exposed finishes. This ability means greener construction options, meaningful use of local natural resources and benefits to the bio-economy.

Our joint study is currently underway at EllisDon’s modular fabrication facility, located in Stoney Creek, Ontario; the facility is an industrial building of over 27,000 square metres that is fully fit for prefabricated volumetric modules and panelized building components. The project will be completed later this year, with ongoing full-scale and long-term testing planned post-study.

Natural Resources Canada’s IFIT program facilitates the adoption of transformative technologies and products by bridging the gap between development and commercialization. IFIT-funded projects help diversify the forest product market through high-value bioproducts such as bioenergy, biomaterials, biochemicals and next-generation building products. The GCWood program supports innovative low-carbon wood construction as part of Canada’s goal of reaching net zero by 2050. The program increases awareness of and capacity for innovative tall wood buildings, timber bridges and low-rise wood buildings.

Lead image by Tango Studio